Our Additive Manufacturing Printers and System

“Diversification of services has always been a key focus in our business to ensure we continue providing relevant, efficient, high-quality support to our clients.”

Darren Clark - Managing Director

“By teaming up with Core Additive and Markforged, and leveraging industrial 3D additive manufacturing capabilities with their existing engineering and design services, CADDS is uniquely positioned to guide clients through the optimisation process for 3D printing solutions.”

Darren Clark - Managing Director

Mark Two™

Flagship Continuous Fiber Composite 3D Printer, built to revolutionize your manufacturing operation.

Metal X™

An accessible end-to-end metal 3D printing solution for functional metal parts, next-day.

FX20™

An ULTEM™ Filament capable large format 3D printer for big, strong, high temp parts — usable from factory floor to flight.

““Industrial Production, anywhere you need it. Print strong parts every time with the reliable and easy-to-use additive manufacturing platform.””

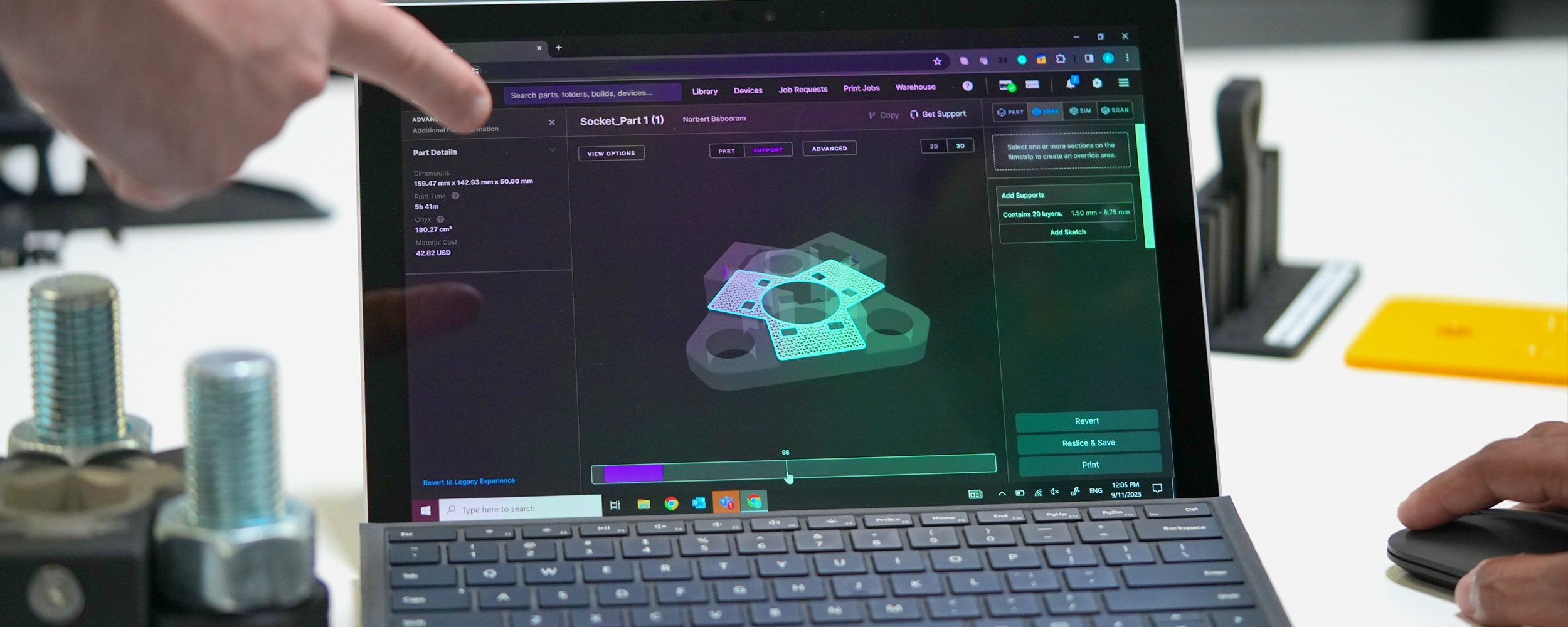

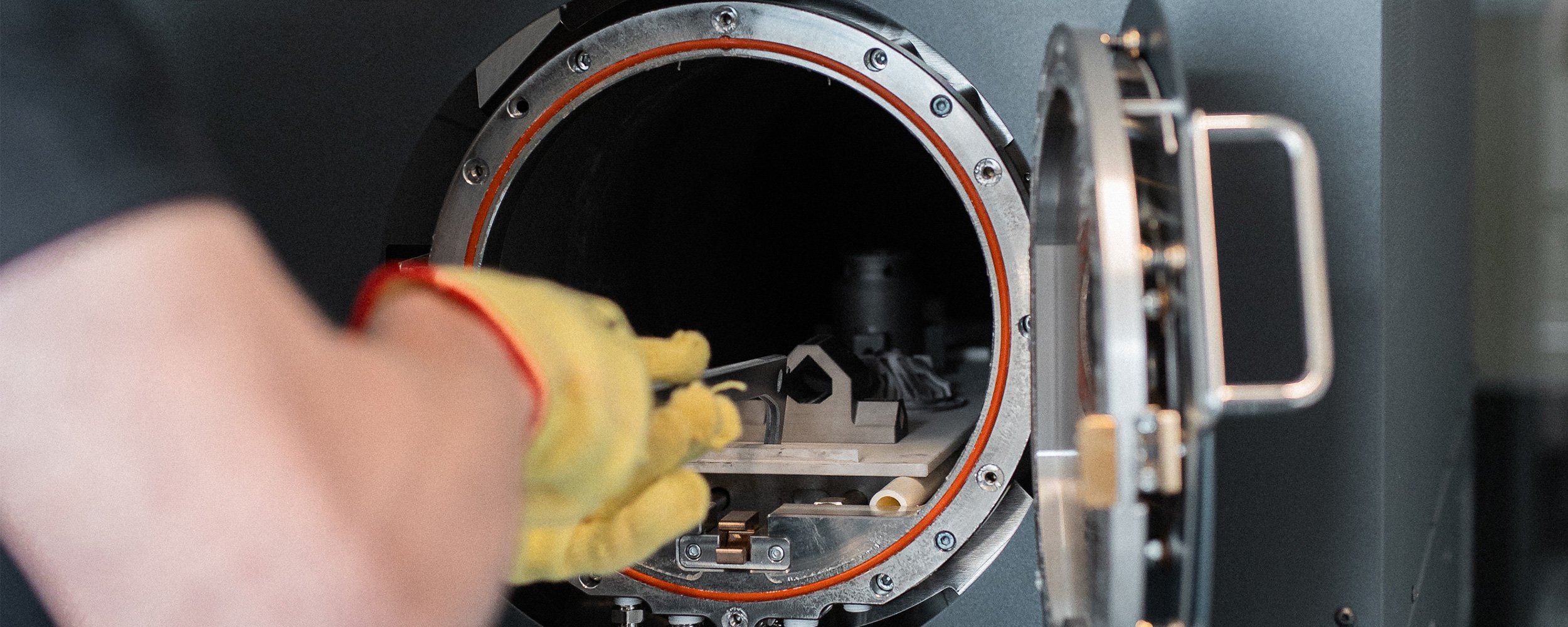

Metal X™ System

The Metal X System is an accessible way to fabricate complex metal parts in a wide variety of advanced metals.

Simple, Yet Powerful

The Metal X is one of the most intuitive metal 3D printers available today. Print a wide range of materials from stainless steels to copper with minimal training on a closed workflow. Scaling up capacity is easy; just add printers.

Safe and Affordable

The Metal X is designed to be safe to use and accessible for all fabricators. It costs several times less than DMLS metal 3D printing systems and requires no dedicated operator, no powder management system, and minimal PPE.

Quality Parts, Fast

The Metal X is purpose-built for consistent part quality and a seamless user experience. Markforged combines superb software, materials research, and an advanced motion system to deliver industrial-grade parts quickly and reliably.

Metal X™ Compatible Materials

17-4PH Stainless Steel

A2 Tool Steel

D2 Tool Steel

H13 Tool Steel

Inconel 625

Copper

MARK TWO™

A leading way to make aluminum-strength parts on your desktop.

Carbon Fiber Strength

Print Continuous Carbon Fiber reinforced parts on your desktop – stiff, strong, extremely durable, and capable of replacing machined aluminum.

Built to Last

A unibody aluminum chassis and precision-machined components deliver lights-out reliability over thousands of print hours.

Precise and Beautiful Parts

Print precise parts with best-in-class surface finish thanks to Onyx, Markforged’s extremely versatile micro carbon fiber filled nylon material.

Mark Two™ Compatible Materials

Onyx™

Nylon

Smooth TPU 95A

Precise PLA

Carbon Fiber

Fiberglass

Aramid Fiber (Kevlar®)

HSHT Fiberglass

FX20™

The FX20 brings the Digital Forge and Continuous Fiber Reinforcement to a new realm of parts, problems, and industries.

Massive Builds, Faster

The FX20 pairs size and throughput to make larger builds at incredible speeds, delivering the transformational benefits of The Digital Forge at a new scale.

Flight-Ready Functional Parts

Built for everything from performance tooling and fixtures to flight-ready production parts — this large format 3D printer can reinforce ULTEM™ 9085 Filament with continuous carbon fiber.

Production-Ready Performance

A precision-designed, sensor-driven production 3D printer delivers breakthrough reliability and performance with a simple user experience.

FX20™ Compatible Materials

Onyx™

ULTEM™ 9085 Filament

Carbon Fiber

Carbon Fiber FR

WE ARE CADDS GROUP.

At CADDS Group, we believe in the power of doing things right. We develop intelligent and integrated solutions to meet the individual demands of every project. We work together to create ongoing benefits for our clients, suppliers, and team.

Our diverse service offering across engineering and design, surveying and scanning, architectural drafting and building design, product design, sustainability, and fabrication, gives us the unique capability to consider every project from multiple viewpoints. We provide a streamlined and cost-effective approach, for the full lifecycle of a project.

Committed to providing the highest quality service and support, our agile and considered methodology allows us to break down even the most complex challenges.

Product and Industrial Design

Our team of dedicated product engineers and product designers can support your ‘blue-sky thinking’ from start to finish. Whether you are looking at developing an entirely new product to take to market or reinvigorating an existing solution, we can help you. From creation and visuals to prototyping and production, right through to post-product support and documentation, our specialist team has the right tools and experience to get you on your way.

Prototyping

Our product design team undertakes the prototyping phase that will ensure real life testing and refinements that will aid in the manufacturing process.

Our CADDS Fabrication department can also help if we need to build large scale prototype.

Download our CADDS Group brochure

Our connected Group creates and delivers innovative and streamlined solutions for all of our clients. Discover how we ensure a new level of service by bringing together a range of specialists working towards a common goal.